In Memoriam, Space Shuttle Columbia (STS-107): They served in peace for all humankind- February 1, 2003

Click on this link to view NASA DAY OF REMEMBRANCE

Why do we need microgravity (weightless) environment to test sand?

All aspects of soil stability, bearing capacity, slope stability, the supporting capacity of deep foundations, and penetration resistance depend on soil strength. The stress-deformation and stress-deformation-time behavior of soils are of importance in any problem where ground movements are of interest. In most engineering materials, the strength is derived from internal chemical and physico-chemical forces of interaction, which bond the atoms, molecules, and particles together. In cohesionless soils, the constitutive relations are mainly derived from interparticle friction between particles and particle groups and dilatancy, and to a lesser extent from particle bonding by weak electrostatic, physico-chemical, and Coulomb forces.

Under moderate-to-high stress levels, the influence of gravity on the behavior of laboratory test specimens may not be pronounced and, therefore, the test results in terrestrial (1-g) environment may be sufficiently conclusive. However at low interparticle stresses, which can result either from low applied (confining) stresses or from excess pore fluid pressures developed within the soil mass without corresponding changes in the applied stresses, the presence of gravitational body forces acting on solid particles and interstitial fluids exerts a pronounced influence on movement of individual particles or particle groups. Such motions, in turn, cause changes in soil fabric which results in significant changes in the interparticle friction forces contributing to the soil’s strength and deformation characteristics.

These experimental limitations on Earth have important implications in geotechnical, planetary, and earthquake engineering. For example, at or near-zero effective stresses, quantitative evaluation of the contribution to soil’s shear strength by particle interlocking cannot be accomplished by direct means at the present time. Yet, this shear strength component may be one of the most important factors affecting the stability of cohesionless earth masses under seismic loading, since it controls arching phenomena and volume changes resulting from dilatancy effects, hence, excess pore fluid pressure build-up or dissipation. The microgravity environment induced by near-orbits of spacecraft provides unique experimental opportunities for testing theories related to the mechanical behavior of soils. It eliminates the effects of specimen weight, specimen size, minimizes the effects of boundary conditions and makes it possible to create a uniform near-zero effective stress state throughout a soil test specimen.

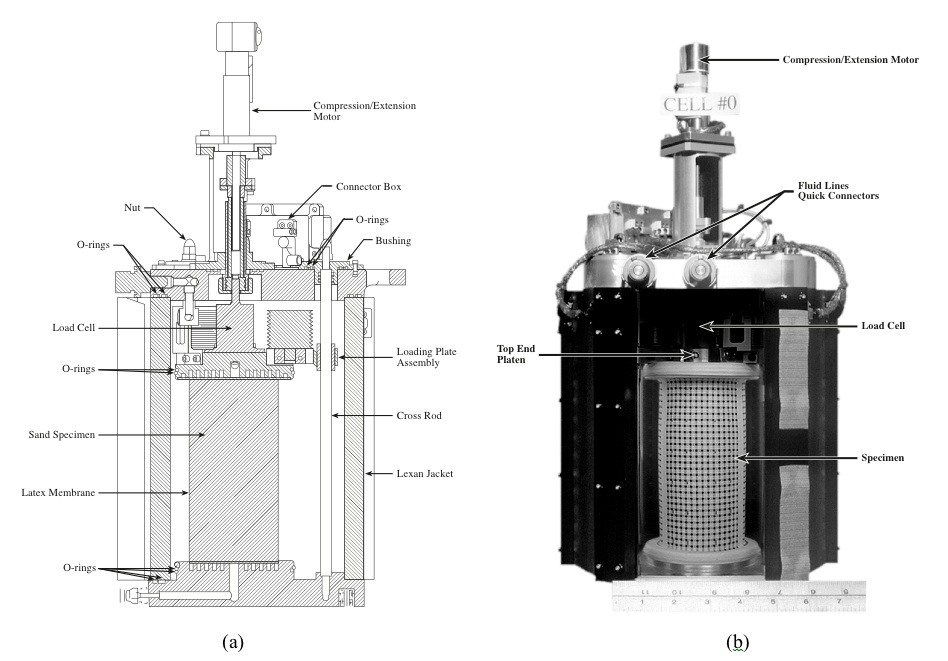

NASA sponsored a project called Mechanics of Granular Materials (MGM) which includes conducting a series of displacement-controlled quasi-static and cyclic triaxial compression experiments in a SPACEHAB module on the Space Shuttle during the STS-79 mission in September, 1996 and the STS-89 mission in January, 1998. The experiments were conducted on right cylindrical specimens 75 mm in diameter and 150 mm long at effective confining pressures of 0.05, 0.52 and 1.30 kPa. The specimens, which were tested in the dry condition, consisted of sub-rounded quartz (Ottawa) sand with average grain size of 0.22 mm. The specimens were prepared in a terrestrial laboratory by slow pluviation (raining) of the dry sand into a natural rubber latex membrane having a thickness of 0.30 mm, supported by a removable cylindrical mold to ensure uniform density at 86.5% (±0.8%) relative density for the STS-79 mission and 65.0% (±1.0%) for the STS-89 mission, based on maximum porosity: 0.446, minimum porosity: 0.327, specific density of the particles: 2.65. The ends of the cylindrical specimens were then sealed by the tungsten carbide end platens. A small amount of vacuum, which was typically in the range of 13 to 35 kPa relative to the outside atmospheric pressure, was applied through one end platen to the pore space within each specimen. The specimen preparation mold was then disassembled and removed. The external test cell (Fig. 1) was then assembled around the specimen, filled with deionized water, and pressurized to 103.5 kPa. The internal vacuum was then removed and the pore space was vented to atmospheric pressure.

Soil Laboratory in the Space Shuttle:

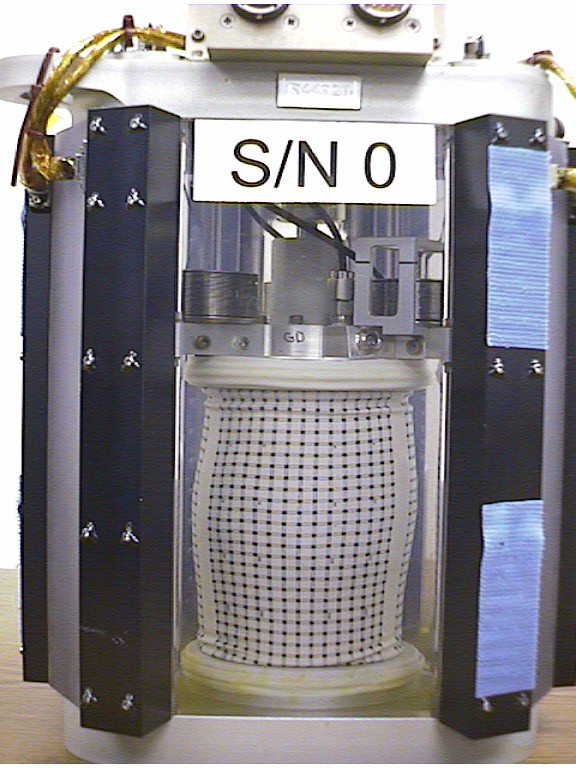

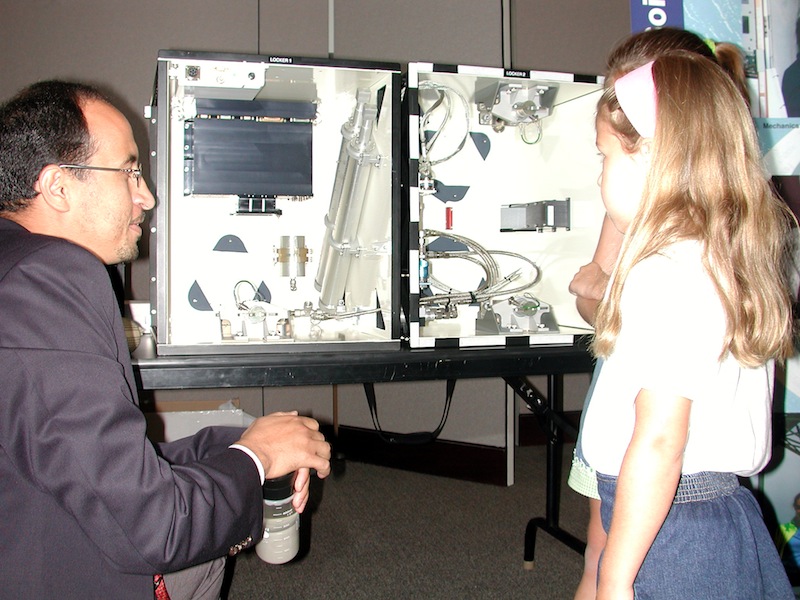

The hardware used to perform the MGM experiments was especially designed and built for this purpose. It was flown three times aboard the space shuttle during the NASA STS-79, STS-89, and STS-107 shuttle missions. It consists of the Twin Double Locker Assembly (TDLA, Fig. 2) which provides structural support for the experiment microprocessor control system, fluid pressure system, Charged Couple-Device (CCD) video cameras, and data recording. they also provide mounting points for three triaxial test cells (Fig. 2) during shuttle lift-off and landing. Each locker measures 420.7 mm wide by 511.2 mm high by 495.3 mm deep. The cylindrical sand specimen (75 mm in diameter and 150 mm long) is contained inside a thin latex membrane and surrounded by water inside the lexan jacket (Fig. 1). The desired confining pressure is attained by pressurizing the water inside the lexan jacket and a stepper motor is used to compress the specimen at a constant displacement rate. More details about the MGM hardware are referred to Alshibli et al. (1996) and Sture et al. (1998).

BEHAVIOR OF SAND IN MICROGRAVITY ENVIRONMENT

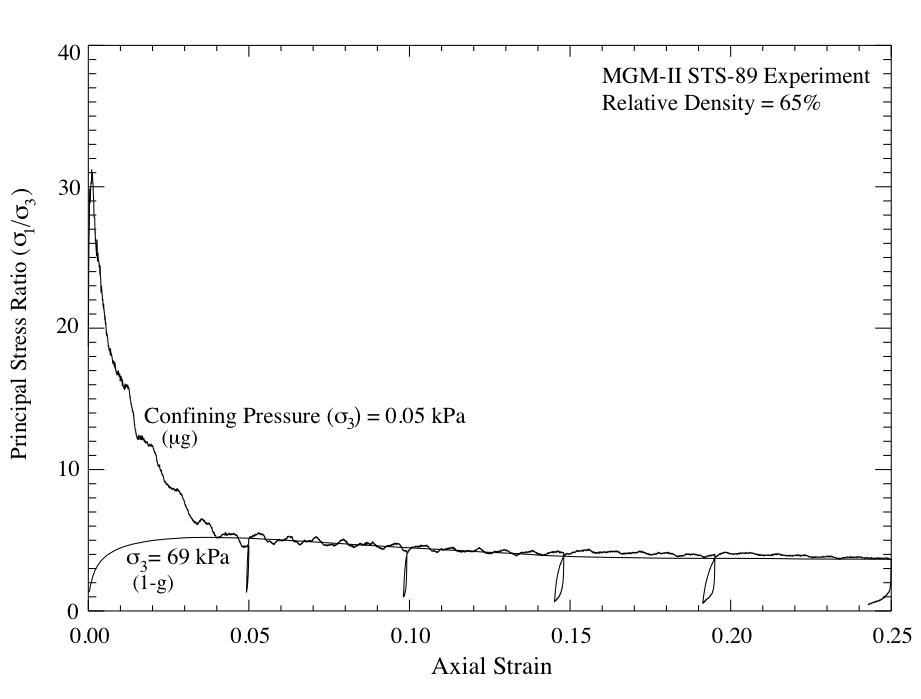

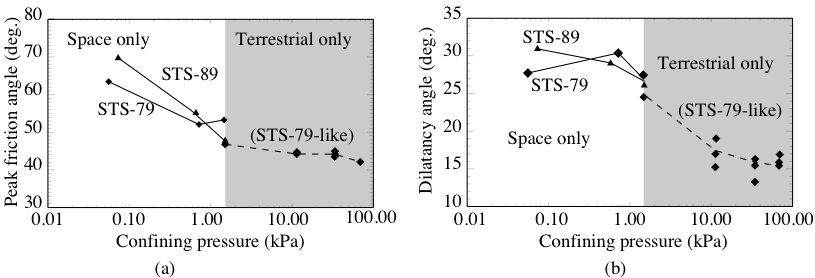

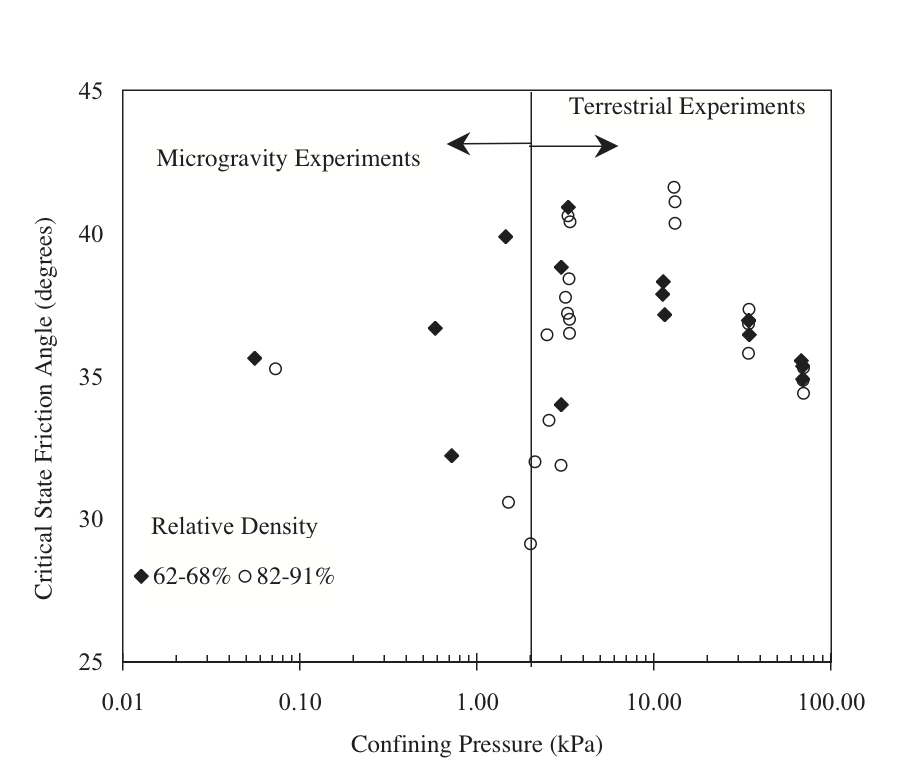

The basic and dominant factors responsible for the strength of cohesionless granular materials is frictional resistance between particles at contact, and rearrangement and interlocking between particles’ groups. Internal friction angle (φ) and dilatancy angle (ψ) are measures of soil’s shearing resistance and volume change, respectively. The results of MGM microgravity experiments show unusually high peak strength friction angles in the range of 47.6 to 70.0 degrees (Figs. 3 and 4a). The properties for the same material at the same density, tested at 13.8 kPa and 34.5 kPa gives angles of 44.1° with standard deviation 0.3 (Bolton, 1986). It was observed that the residual strength levels were in the same range as that observed at higher confining stress levels (Fig. 3). The dilatancy angles were unusually high in the range of 30 to 31 degrees (Fig. 4b). All specimens display substantial initial stiffnesses and elastic moduli during unloading and reloading events, which are nearly an order of magnitude higher than conventional theories predict. The stress-strain traces are characterized by distinct periodic oscillations in stress of similar frequency, amplitude, and pattern in some of the experiments, as inelastic deformations dominant the overall responses. The amplitude of the oscillations increases with confining pressure, being most pronounced in the 1.30-kPa experiments. This oscillatory behavior is to a large extent attributed to periodic instabilities, which appear to result from buckling and degradation of multiple discrete internal arches and columnar systems (Jaeger et al., 1996 & 1997). These mechanisms appear to be significantly suppressed in terrestrial experiments at higher confining stress levels (Fig. 3).

Following the shuttle flights, the specimens were stabilized by low viscosity epoxy and the internal features were studied using nondestructive x-ray Computed Tomography (CT) techniques provided by the Non-Destructive Testing and Evaluation facility of Los Alamos National Laboratory and the Kennedy Space Center Computed Tomography System. Data from each specimen consists of cross-axial slices at 1 mm vertical spacing. The slices were used to construct 3-dimensional volumetric images of the specimen, and inner features may then be examined by exposing internal planes. In the images shown in Fig. 5 darker colored pixels represent areas of lower densities, generally where the material has dilated during shearing. Circular shear cones are seen extending at large angles from each end of the specimens, though the cone on the stationary end platen is more clearly developed. A large number of inclined, radial discrete bands of lower density, similar in shape to turbine blades mounted on a central hub, extend outward from the boundary of the cones. The cones are clearly defined by the specimen-end-platen interface friction and the restraint posed by the stretched latex membrane in the external contact region.

Photos taken during NASA Space Shuttle Missions

Public/ Outreach Activities:

ACKNOWLEDGMENTS

The MGM team gratefully acknowledges the financial support provided by NASA/ George C. Marshall Space Flight Center under contract No. NAS8-38779.

Related Publications:

- Fratta, D. and Alshibli, K. (2005) “Implications of Process Monitoring of Lunar/Martian Regolith by Means of Wave Propagation – Experience in Geotechnical Engineering”, Workshop on Granular Materials in Lunar and Martian Exploration, NASA/ Kennedy Space, Center, Feb. 2-3, 2005.

- Sture, S., Alshibli, K. A., Batiste, S. N., Lankton, M., and Parisi, J. (2005) “Engineering Properties of Granular Materials Under Very Low Effective Stresses”, Workshop on Granular Materials in Lunar and Martian Exploration, NASA/ Kennedy Space, Center, Feb. 2-3, 2005.

- Sture, S., Alshibli, K. A., Batiste, S. N., Lankton, M., and Parisi, J. (2005) “Vibratory Methods for Efficient Regolith Excavation and Construction”, Workshop on Granular Materials in Lunar and Martian Exploration, NASA/ Kennedy Space, Center, Feb. 2-3, 2005.

- Alshibli, K. A., Batiste, S. N., and Sture, S. (2003) “Strain Localization in Sand: Plane Strain Versus Triaxial Compression”, ASCE, Journal of Geotechnical & Geoenvironmental Engineering, Vol. 129, No. 6, pp. 483-499, DOI: http://dx.doi.org/10.1061/(ASCE)1090-0241(2003)129:6(483)

- Sture, S., Costes, N., Batiste, S., Lankton, M., Alshibli, K., Jeremic, B, Swanson, R., and Frank, M. (1998) “Mechanics of Granular Materials at Low Effective Stresses” ASCE, Journal of Aerospace Engineering, Vol. 11, No. 3, pp. 67-72, DOI: http://dx.doi.org/10.1061/(ASCE)0893-1321(1998)11:3(67)